A new 50.8mm class DTH hammer from Rockmore International

June 7, 2014

Rockmore International Launches First Hammer in New T Series Line

November 20, 2014Rockmore Launches The New T Series DTH Hammer Class

Rockmore International, a global manufacturer of percussive rock drilling tools, has recently launched the T series DTH hammer line and introduces the first model in this class – the ROK 600T. The new T hammer line will be officially unveiled at the upcoming National Ground Water Association exhibition held in Las Vegas, Nevada in December 2014.

This new addition to Rockmore’s existing broad range of DTH hammers is a breakthrough for DTH drilling technology for mining, construction, and water-well applications. In addition to its ultra high performance features, the new T series design hammers utilize drill bits with standard shank connections that no longer require plastic parts commonly known as Blow Tubes or Foot Valves. The elimination of this plastic part associated with the drill bit offers various technical and economical advantages.

“We recognized a trending demand in the DTH drilling sector for a high performance DTH tool that could utilize industry standard drill bits without plastic components in order to increase reliability yet not compromise drilling efficiency,” comments Mr. Pejman Eghdami, Executive Vice President of Rockmore International.

The new T series DTH hammer design is the result of extensive research, development, and field testing. The T series is “Tubeless”, as the name suggests (utilizing bits without plastic Blow Tubes), and achieves the goal of using industry bit shank connections, but without the plastic component imbedded in the bit. Although the “Tubeless” DTH hammer has been offered before, drilling performance was often compromised when designed to operate with an industry standard bit shank. In addition, other manufacturers have introduced DTH hammers that utilize bits without a plastic component, but such DTH bits are proprietary in design, which limit their availability.

“With our emerging T class DTH hammers, we are offering the drilling community a balanced solution of improved reliability without compromising any drilling performance. And impressively, we have achieved this by incorporating standard industry shank connections into the overall design concept,” states Mr. Eghdami.

There are clear economical advantages of eliminating the traditional plastic components from the bit shank section. Blow Tube / Foot Valve breakages on DTH bits during drilling operations are catastrophic since the hammer will cease to function immediately. This is particularly damaging to drill time efficiency if such interruptions occur in deep-hole applications, requiring the hammer to be retrieved out of the hole for bit replacement. The T series hammers will alleviate such costly down time by elimination of the plastic bit component that is susceptible to breakage.

The ROK 600T is a six inch class model with high performance drilling characteristics rated for drilling 6.1″ to 7.0″ (155 to 178mm) diameter holes for blast hole applications in mining and construction. It is also suitable for water well drilling since it exhibits good in-hole flushing which is necessary to evacuate rock chips in deep applications.

As a T series design feature, the ROK 600T accepts the industry established bit shank model QL60, but with the Blow Tube / Foot Valve removed. Such standard bits are readily available from established supply channels in the mining, construction, and water-well markets. The corresponding bit connection for this hammer is designated by Rockmore as QL6T, which has an identical shank design to the QL60, but without the Blow Tube / Foot Valve.

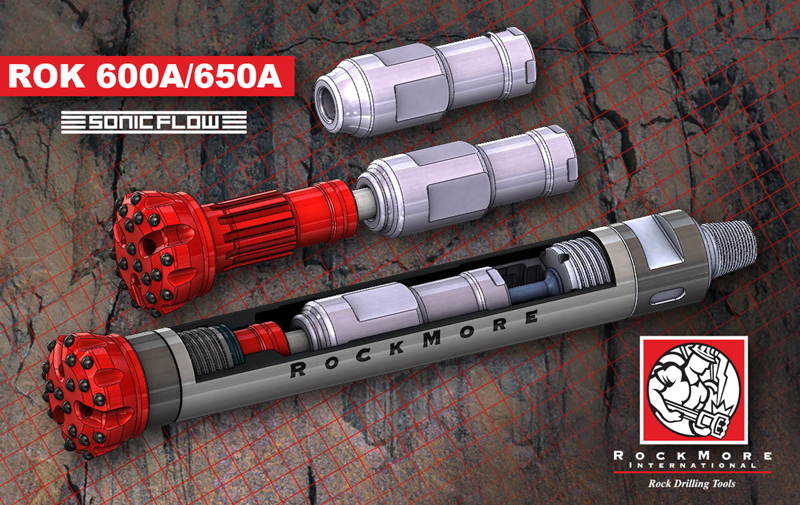

As with all of Rockmore’s DTH hammers, the new ROK 600T takes full advantage of Rockmore’s patented SonicFlow technology, which optimizes airflow by simplifying and streamlining the air paths to minimize backflow and turbulence, thus delivering more energy to the piston. Field testing of the SonicFlow design was determined to result in faster penetration rates and greater overall DTH hammer efficiency.

Rockmore International is a global manufacturer of rock drilling tools, serving the mining, construction, and water-well sectors for more than 65 years.