Manufacturers spotlight: Rockmore International

August 11, 2005

New XR32 Thread Design for Drifting and Tunneling

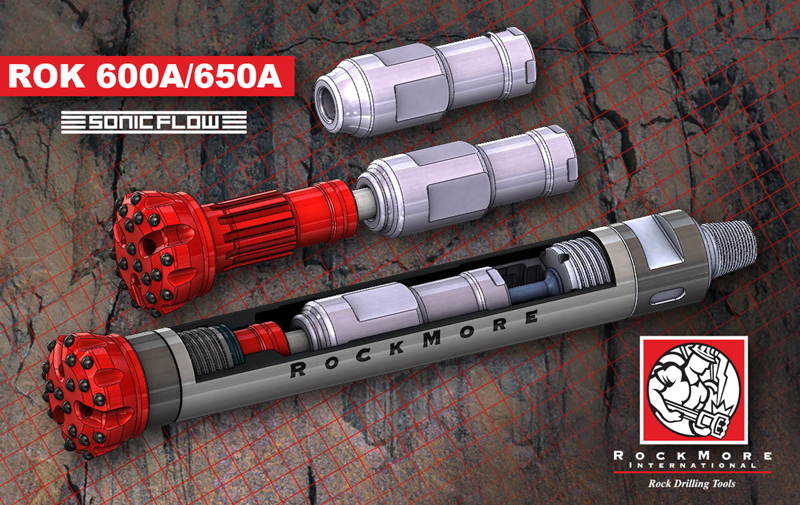

June 10, 2008The ROK – Rockmore’s High Performance DTH Hammer

Rockmore International announces the newest design of DTH hammers, the patent-pending ROK, which is based on their development of SonicFlow Technology. Offered in 3-8” diameter ranges, for drilling applications in mining, quarrying, water-well and gas fields, these hammers are designed to maximize the high-pressure airflows for overall greater efficiency.

Previous to the ROK, airflow paths in DTH hammers have been subject to making more multiple turns through angled orifices, which often creates flow-turbulence and pressure changes. To lower the turbulence, maximize airflow continuity, and increase hammer performance, the Rockmore engineering team developed the concept of SonicFlow Technology.

With substantial time spent on design, modeling, and testing, this new technology strongly increases airflow efficiency within the ROK hammer and ensures that the high pressure air paths are optimized to deliver the greatest amount of energy to the piston.

At the center of the SonicFlow concept is the new, patent pending, Top Sub. As pressurized airflow enters this new component, it is efficiently distributed through strategically located ports. These radial port designs provide the perfect paths for the airflow to enter the hammer chamber at a high velocity and with minimal back-flow interference. Also, to minimize the back-flow of air and debris into the hammer, an efficient check-valve system has been incorporated in the Top Sub design.

The new SonicFlow hammer features a radically new piston design with distinguished physical features, all of which evolved from the airflow design. Easily, the most notable of these features is the venturi-shaped radius located in the top of the piston. This radius reduces any undesired turbulence in the chamber and increases airflow pressure in the pistons air-cycles, leading to higher energy transfers between the pressurized air and the piston.

During the design and testing stages, Rockmore engineers found that by simplifying and minimizing the number of individual components used in the hammer design itself, allowed for more direct and unrestricted air paths, less wear points, and simpler service.

With more impact energy to the bit, higher penetration rates, and an overall better performance, SonicFlow Technology raises the standard of the airflow characteristics within the ROK hammer.