Rockmore’s New Austrian Facility

March 19, 2012

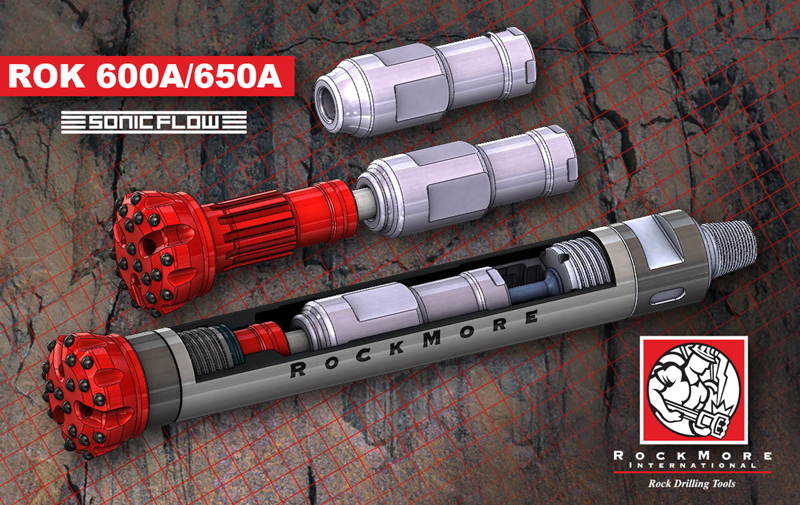

New DTH Hammer from Rockmore

July 10, 2012Rockmore Announces New ROK 500DH DTH Hammer

Rockmore International announces a new DTH hammer in its emerging Deep Hole series, the ROK 500DH. This 5 inch range hammer incorporates many new innovations and features characterized in the new Deep Hole class of DTH hammers.

The ROK 500DH is the first release in Rockmore’s newly announced Deep Hole hammer series. As a 5 inch class hammer, the 500DH is targeted to drill 5.50 inch (140 mm) to 6.00 inch (152 mm) diameter holes. Designed to increase drilling effectiveness and efficiency in deep hole applications, the ROK 500DH incorporates engineering advancements for drilling in DTH applications such as geothermal, exploration, water-well, and in other mining and construction sectors. Unique drilling requirements in such applications often demand drilled holes exceeding 1,000 ft (300m) deep and include high volumes of water, thus presenting great challenges for conventional DTH hammers to drill effectively.

The ROK 500DH has been designed specifically to handle such challenges by incorporating new airflow and component design advancements, primarily in the air ports of the wear sleeve and piston. The hammer is rated for use with large compressors: 24.1 Bar (350 PSI) at 25.2 m3/min (890 SCFM), however, it can readily accept greater air volumes and pressures from larger air compressor packages. The upper and lower hammer air chambers of the 500DH have been modified accordingly in order to achieve optimum drilling efficiency. The advanced piston design also offers maximum blow energy with each stroke to the bit, allowing for superior hammer and bit penetration rates in all drilling conditions.

A new bit retention system was also developed for this hammer in order to alleviate broken bit heads falling to the bottom of drilled holes when bit shanks fail catastrophically. A new bit shank, the DH500, was developed in conjunction with the new retention system, eliminating the need for bit retaining rings present in conventional hammer designs. The bit is retained in the driver sub by uniquely designed lobes located on the bit shoulder. If in the unlikely event that the bit breaks from the shank body during drilling operations, the bit head may be retracted out of the hole as retained by the lobes on the bit and driver sub, thus eliminating bit retrieval that is often timely and costly.

The traditional foot valve, or blow tube component, has also been eliminated in the DH500 shank concept. Foot valve breakages on DTH bit shanks during drilling operations are catastrophic since the hammer will cease to function immediately after such a failure. This is particularly damaging to drill time efficiency if such interruptions occur in deep hole applications, requiring the hammer to be retrieved out the hole for bit replacement. The DH500 shank alleviates such down time risk by the elimination of the foot valve component.

Conventional hammers often exhibit low penetration rates when used in deep hole applications when high water volumes exist in the hole while drilling. But due to the design advancements mentioned above, the new ROK 500DH drills exceptionally fast in dry hole conditions as well as under high water volumes exceeding 150 gal/min (9.5 lit/s) flow rates at the hole annulus. There is no compromise, therefore, in high drilling penetration rates with or without high water volumes.

As with all of Rockmore’s DTH hammers, the 500DH take full advantage of Rockmore’s patented SonicFlow technology, which optimizes airflow by simplifying and streamlining the air path to minimize backflow and turbulence, thus delivering more energy to the piston. Optional back reaming buttons on the top sub also contribute to increase hammer life. Field testing of the SonicFlow design was found to result in faster penetration rates and greater overall DTH hammer efficiency.

The ROK 500DH has been engineered to withstand the toughest rock drilling conditions. The solid piston design is made from an advanced material that is case hardened, combining high strength with supreme wear resistance. The high frequency, reciprocating piston is designed to strike the bit with maximum force. An innovative design, unique to Rockmore hammers, reduces the number of hammer components, thus reducing the amount of component wear points, making hammer service simpler and less expensive. Unique lead threads on the top sub and driver sub ensure easy coupling and uncoupling of the hammer.

Rockmore International is a global manufacturer of rock-drilling tools, serving the mining, construction, and water-well sectors for more than 60 years. www.rockmore-intl.com.